Update:The stability of acrylic emulsion involves the problems of demulsification, deterioration and delamination under storage...

The stability of acrylic emulsion involves the problems of demulsification, deterioration and delamination under storage, transportation, processing and high and low temperature conditions. Generally, the most concern is the stability under high temperature, long-term storage at room temperature, and freeze-thaw cycles.

1. High temperature stability

Take dozens of grams of acrylic emulsion and put it in a plastic sealed bottle, keep it in a constant temperature oven at a certain temperature, and observe whether there is delamination, gelation, demulsification, discoloration and curing every day. The high temperature stability of the acrylic emulsion can be passed if it is placed in the oven for at least 5d without obvious change.

2. Freeze-thaw stability

The acrylic emulsion sample put into the sealed bottle was frozen in a refrigerator of minus ten degrees for 18 hours, taken out and placed at room temperature for 6 hours to observe whether there was delamination, gelation, demulsification, discoloration and solidification. The operation is usually repeated at least 3 times, and the freeze-thaw stability is passed if there is no change.

3. Room temperature storage stability

The actual storage of acrylic emulsion samples, regular observation of results is a more reliable and convincing conclusion of stability than high and low temperature tests. Samples of each batch of acrylic emulsion should be kept for actual storage and regularly observed to accumulate stability data.

4. Dilution stability

Take a certain amount of acrylic emulsion, add deionized water to dilute it, and observe whether precipitation, demulsification and flocculation occur. Sometimes it is necessary to add a certain amount of water and observe whether there is any abnormality overnight. A stainless steel bar is cold at one end and heated at the other end, and the entire bar has a uniform temperature gradient, from minus a few degrees Celsius at one end to more than 100 degrees Celsius at the other end. The stainless steel bar has a stepless temperature display along the line. Apply the acrylic emulsion to the strips. After a period of time, the acrylic emulsion on the strip forms a transparent and uniform film on one side, and the acrylic emulsion on the other side becomes cloudy and broken, and the middle boundary is clear. The temperature indicated by this line is the minimum film-forming temperature of the acrylic emulsion.

During the test, adjust the instrument to the required value according to the operating regulations and the required temperature range. Special attention should be paid to turning on the cooling water first to prevent the cooling element from being burned out when the machine is turned on. After confirming that the temperature on the measuring plate has reached equilibrium, start to apply the sample. In order to ensure the uniform thickness of the acrylic emulsion coating film, first attach a certain thickness of adhesive tape to the test plate, then use a rubber scraper to evenly coat the acrylic emulsion in the groove of the adhesive tape, and cover the upper cover. Turn on the air pump, blow dry air through the upper part of the acrylic emulsion, and pay attention to observe the film formation of the acrylic emulsion. As mentioned above, it can be seen that there will be obvious differences in the state of the film formed by the acrylic emulsion. The film-forming part is a continuous and transparent film, while the other part is intermittent or even white powder. The temperature at the boundary line between the two parts is determined as the minimum film-forming temperature of the acrylic emulsion.

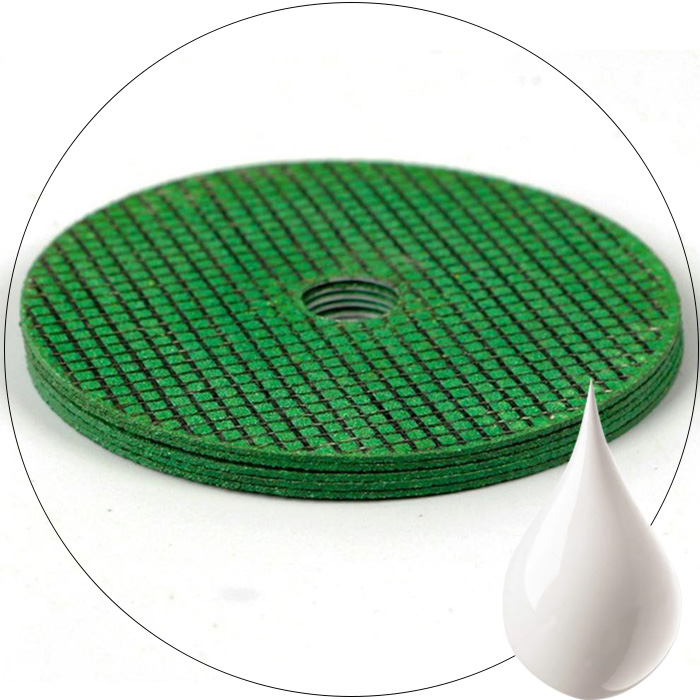

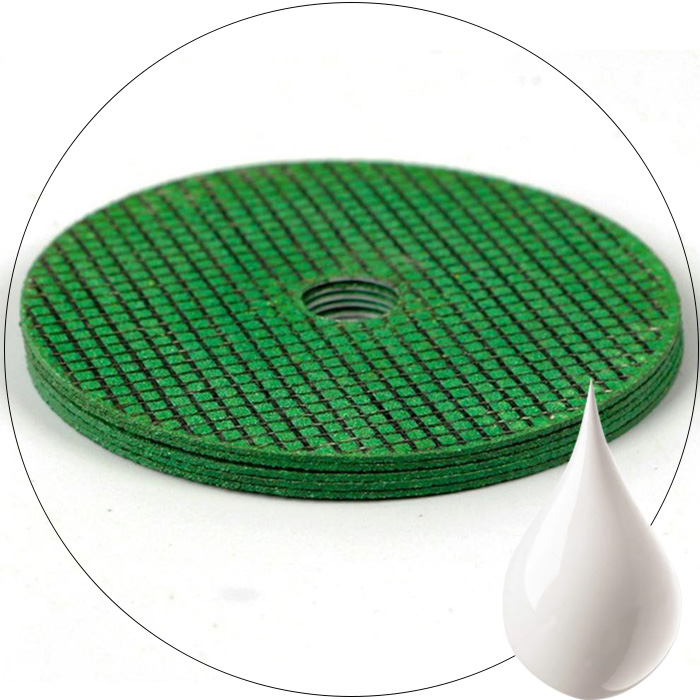

Fiberglass mesh for grinding wheel

Fiberglass mesh for grinding wheel